To meet the challenge of designing power sub-systems, many designers are considering using power modules instead of traditional discrete POL designs, with time to market, size constraints, reliability and design capabilities being motivating factors.

Today’s power systems for communications and computing infrastructure support high current loads from increasingly power-hungry FPGAs, ASICs and microprocessors.

To supply these high current circuits, equipment makers often rely on discrete power solutions that are complicated, take up valuable real estate and may have significant power output limitations.

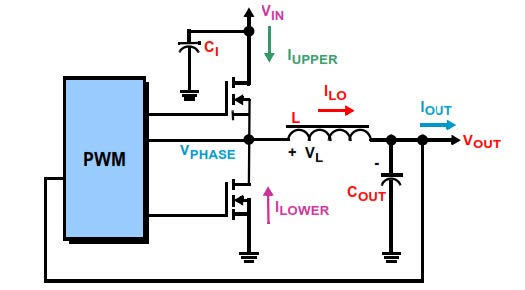

Step-down (buck) regulators are used to convert power from a distributed power bus to the individual point-of-loads (POLs) in infrastructure systems. Step-down converters convert a voltage from an input source to a lower output voltage. They are capable of converting a voltage source (typically 5V to 25V or higher) into a lower regulated voltage (normally 0.5V to 5V).

More recent infrastructure systems may utilize 20–40 point-of-load (step-down) converters in a single system, each with different output voltage and current requirements, creating a challenge for system power supply design engineers.

To meet the challenge of designing the power subsystem for these systems, many designers are considering using power modules instead of traditional discrete POL designs, with time-to-market, size constraints, reliability, and design capabilities being motivating factors.

In many designs, the PCB layout becomes a critical part of overall power performance. Discrete solutions require careful placement of inductors, MOSFETs, capacitors, and controllers on the PCB to minimize noise, reduce EMI, and achieve thermal balance. This adds significant engineering effort and often extends development cycles. By contrast, integrated power modules simplify the PCB design process because most power components are already optimized and enclosed in a single package. Engineers only need to route a few connections on the PCB, enabling faster prototyping and reducing layout-related failures.

Additionally, as power density increases, PCB thermal management becomes more challenging. Discrete POL solutions spread heat across multiple components on the board, requiring complex copper pours, thermal vias, and sometimes even heat sinks. Power modules, however, are designed with internal thermal optimization, helping engineers achieve better overall thermal performance with less PCB area.

In this article, we will compare the benefits of using an integrated power module versus a discrete step-down switching regulator.